European QQ Gummy Candy Production Line: Smaet ,Efficient,and Leading the Way!

The gummy candy industry is undergoing a transformative upgrade from "traditional manual production" to "smart manufacturing".A highly automated,precise,and efficient gummy candy production line is injecting new vitalilty into the industry,achieving dual breakthroughs in quality and production capacity.

The gummy candy industry is undergoing a transformative upgrade from "traditional manual production" to "smart manufacturing".A highly automated,precise,and efficient gummy candy production line is injecting new vitalilty into the industry,achieving dual breakthroughs in quality and production capacity.

25 Cans/Minute

European QQ Gummy Complete Line Praised For Smart Packafing

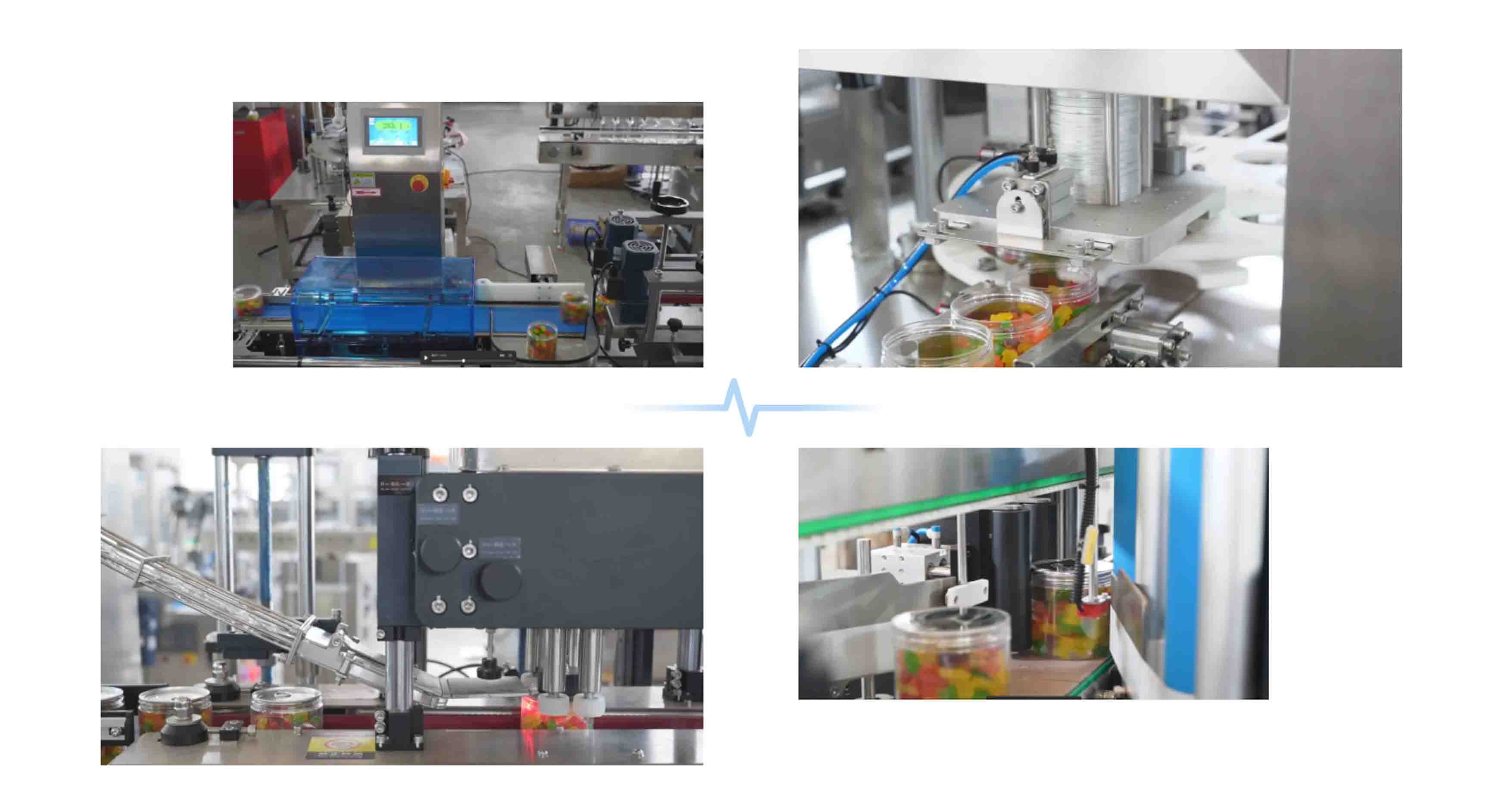

What kind of synergy will emerge when the chewy texture of QQ gummy candies meets the high efficiency of an intelligent production line? Recentiy, a customized 7-can-type complete line for QQ gummy candies,tailored to a European client,delivered an impressive performance with a stable speed of 25 cans per minute.The client couldn't help but praise it as "Awesome", fully demonstrating the strong capabilities of smart packaging in the food production field.

Core Links:

Precision and Efficiency,Zero Errors from Bottle Arrangement to Candy Vibrating

The efficiency of the production line starts right from the source.The bottle unscrambler acts like an "intelligent sorter", quickly arranging round and square bottles with absolute precision,laying a solid foundation for the subsequent packaging processes.The design of the Z-lifter is even more ingenious:by combining candy vibrating with Teflon material, it directly achieves a "zero candy sticking"effect.Every single gummy candy maintains a smooth and intact state,perfectly preserving the product quality.

The weighing and inspection links are equally meticulous. The 10-head cheese weigher adopts a 60° slide-type weighing design, which not only operates at high speed but also controls the error within 0.5 grams, ensuring that each can of gummy candies has a consistent and accurate weight. The metal detector and checkweigher with thin-axis rejection system act as "strict inspectors"; once defective products are detected, they are immediately rejected, leaving no room for substandard products and ensuring the quality of products leaving the factory from the source.

Sealing and Packaging:

Four-Step Process + Multiple Solutions, Balancing Stability and Flexibility

In the sealing process, the production line performs an "efficient four-step sequence" — can sealing, lid placing, servo-driven capping, and aluminum foil electromagnetic sealing are completed in sequence, achieving instant hermetic sealing of the cans. This process not only operates quickly but also maximizes the stability and safety of the packaging, preventing issues such as candy leakage and moisture absorption during transportation.

The production line can also easily meet diverse packaging needs. Laser coding quickly marks product information; the dual labeling function for flat/square bottles and round bottles, combined with the steam shrink labeling function, allows for instant "packaging transformation" of products. Whether it is bottles of different specifications or differentiated label designs, the line can adapt efficiently, greatly enhancing production flexibility.

Intelligent Control: One Person for Supervision, Stable Output of 25 Cans/Minute

The intelligence of the entire production line is also reflected in its user-friendly operation. The dual EU distribution boxes are arranged in a centralized layout, enabling a single operator to easily supervise the entire process and monitor the production status in real time. With this design, the production line can continuously operate stably at a speed of 25 cans per minute. It not only reduces labor costs but also avoids human operation errors, realizing efficient mass production.

From bottle arrangement and weighing to sealing and labeling, this European 7-can-type complete line for QQ gummy candies redefines the standards for gummy candy packaging through a series of intelligent designs and efficient links. It has not only won the client's praise but also proven the empowering value of smart technology in food production. In the future, such intelligent production lines may become a "production asset" for more food enterprises.