Snap! Looking in tropical freshness-Latin American

banana chip's ultra-fast freshness-looking packaging technology

Fried banana chips, a quintessential Latin American snack, boast a golden, crispy texture and rich tropical aroma, deeply embedded in the daily lives of locals. To achieve large-scale production of fried banana chips while maintaining their freshness over time, a specialized packaging line tailored to their unique characteristics is essential. Addressing the core challenges of preserving crispiness and maintaining shape, we have developed a highly efficient and intelligent packaging solution. This solution precisely meets the production demands of this distinctive snack.

Unlock the lock fresh password and take you straight to the core process of packaging fried banana slices

See how we can steadily seal the full crispness and aroma

To address the crisp yet fragile nature of fried banana chips, we specifically selected a Z-type elevator for conveying. This equipment employs a gentle transport method, delicately delivering the banana chips to their designated location. This approach minimizes breakage to the greatest extent possible, ensuring the chips reach the next production stage in perfect condition.

Next comes the precision dispensing stage: Food-grade work surfaces are smooth and easy to clean, fundamentally preventing contamination. Fully automated feeders and high-precision combination scales form an ideal partnership, automatically completing feeding and weighing without any manual intervention. Milligram-level accuracy ensures consistent production standards while enabling efficient mass production.

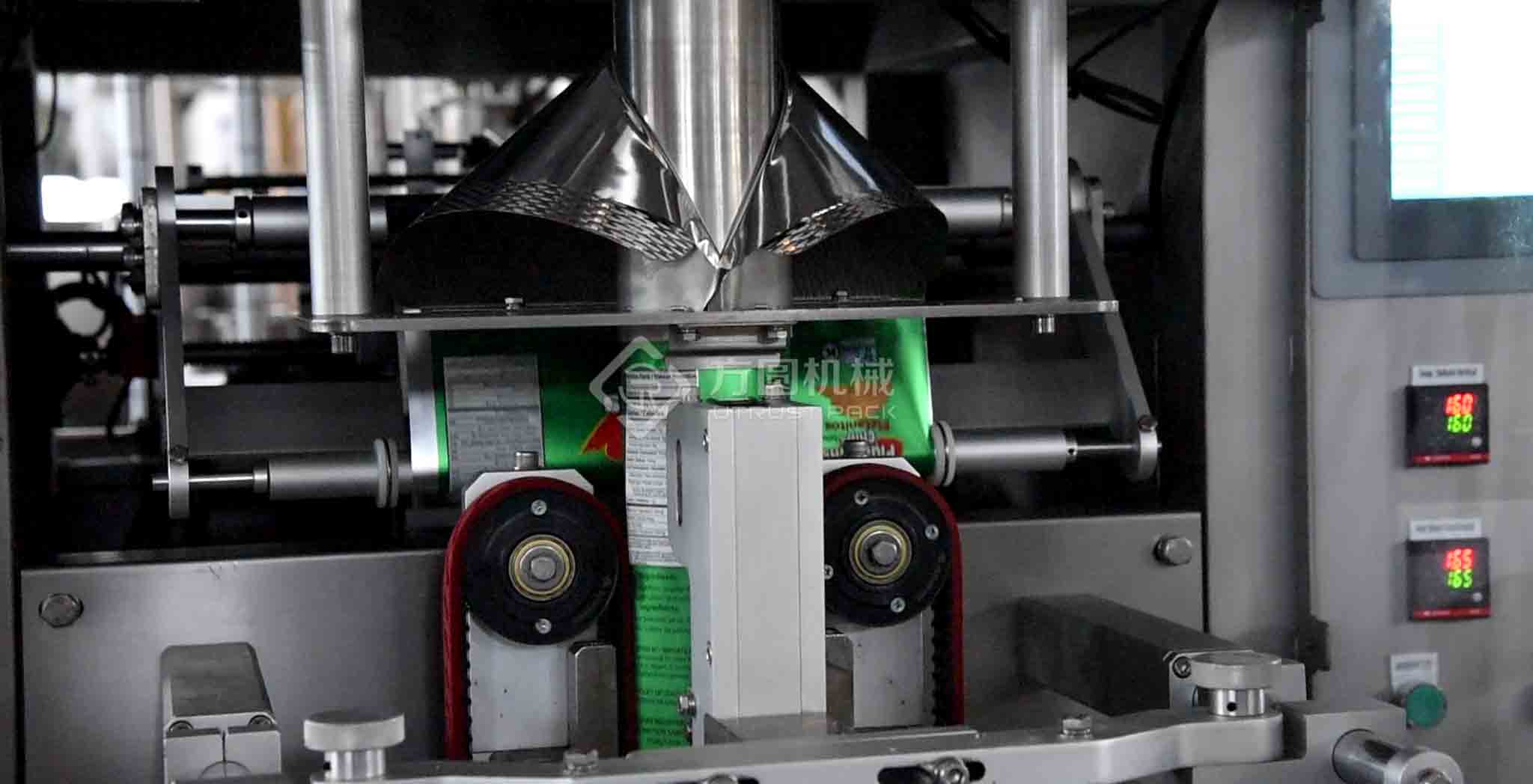

To address the challenge of fried banana chips becoming soft upon exposure to air, we introduced a high-speed vertical bag packaging machine. This equipment achieves a sealing speed of up to 80 bags per minute, effectively minimizing the chips' contact time with air and thereby reducing loss of crispness. From bag forming and filling to sealing, the entire packaging process is completed seamlessly. The tightly locks in freshness. Additionally, it flexibly adapts to the varying demands of multi-batch production.

In terms of food safety, the production line features dual safeguards: throat-type metal detectors precisely remove minute metallic contaminants to ensure products meet safety standards;UV laser coders print permanent anti-counterfeiting marks, making production information clearly traceable, This not only facilitates management but also gives consumers greater peace of mind when purchasing.

The final step involves the core technology of freshness preservation, which utilizes a customized nitrogen generation system to achieve “nitrogen-based freshness locking." To address the issue of fried banana chips easily oxidizing, this device injects high-purity nitrogen into the packaging while rapidly removing oxygen. As a result, the banana chips are less prone to softening or flavor alteration. In an oxygen-free, but the crispiness and aroma of the banana chips at the time of production are effectively preserved. This enhances the product's competitiveness and opens up broader market opportunities.

We are committed not only to addressing current challenges

but also to planning for your future

This customized production line for deep fried banana slices, with its efficient. safe, and flexible design, has successfully solved the key challenges of large-scale production and preservation of tropical snacks.

We believe that a good packaging line should fit the product itself, not just follow the standard version.Whether its' snacks or other foods, we will design intelligent solutions to improve their efficiency and quality. If you also need customized production lines, we are happy to provide you with suitable solutions, utilizing professional technology to protect the uniqueness of your products.